Why our audits matter for our customers

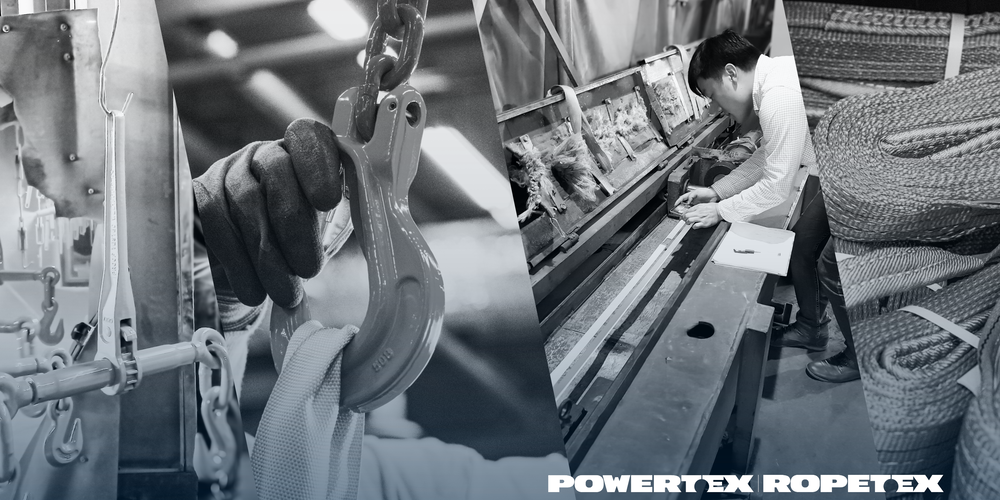

When you see a Powertex or Ropetex label on a product, you expect it to perform safely, reliably, and without compromise. But what gives us the confidence to make that promise? The answer lies in the way we manage audits and quality controls.

Our teams carry out commercial, quality, and sustainability audits directly with producers. We test products against strict standards, maintain technical files, and closely oversee every step in the supply chain. These processes may happen behind the scenes, but our customers feel their impact directly.

Safety first, every time

Lifting equipment is only as good as its ability to perform safely. That’s why every Powertex and Ropetex product is produced according to European and/or Australian standards, with additional requirements we set ourselves. By auditing production partners, testing production lots, and checking batches, we ensure that products can be trusted on-site, whether it’s a sling on a construction site or a wire rope in an overhead crane.

For customers, this means fewer risks, fewer failures, and the confidence that the equipment will perform reliably every day.

Minimizing downtime, maximizing reliability

Downtime is costly. An equipment failure can halt operations, delay projects, and impact safety. Our audits help prevent that. By sampling batches, reviewing production processes, and following up on any reported issues, we keep reliability high across our product range.

That reliability translates into smoother operations for our customers. It means fewer disruptions, less wasted time, and more consistent job performance.

Compliance made easy

For most customers, compliance isn’t optional; it’s a legal obligation. Powertex and Ropetex audits ensure that all products meet European and/or Australian directives, come with complete documentation, and carry all required markings.

This makes it easier for procurement teams, operations managers, and safety officers to demonstrate compliance in their work. Our products don’t just support operations; they also help our customers meet their regulatory and ESG responsibilities.

Full traceability and fast response

Another benefit of our thorough work process is traceability. Every product we sell can be tracked back to its manufacturer, batch, and technical documentation. If an issue ever arises, we know exactly where to look and how to act quickly.

For customers, this means problems are resolved faster and with greater transparency. It’s part of our commitment to accountability; we don’t just supply products; we stand by them.

Value that goes beyond the price tag

At first glance, audits and controls may seem like internal processes. But they’re a core part of the value we deliver. They mean safer products, fewer disruptions, easier compliance, and faster resolutions.

It’s a system designed to not just meet expectations but exceed them. When our customers choose Powertex and Ropetex, they’re not only buying lifting equipment; they’re buying peace of mind.