How Powertex and Ropetex help manufacturers raise the bar on sustainability

At Powertex and Ropetex, we believe that sustainability starts long before a product reaches your site. It begins with how and where it is made. That is why we regularly carry out on-site compliance audits with our suppliers. These audits focus on compliance with our Code of Conduct, social responsibility, and environmental practices.

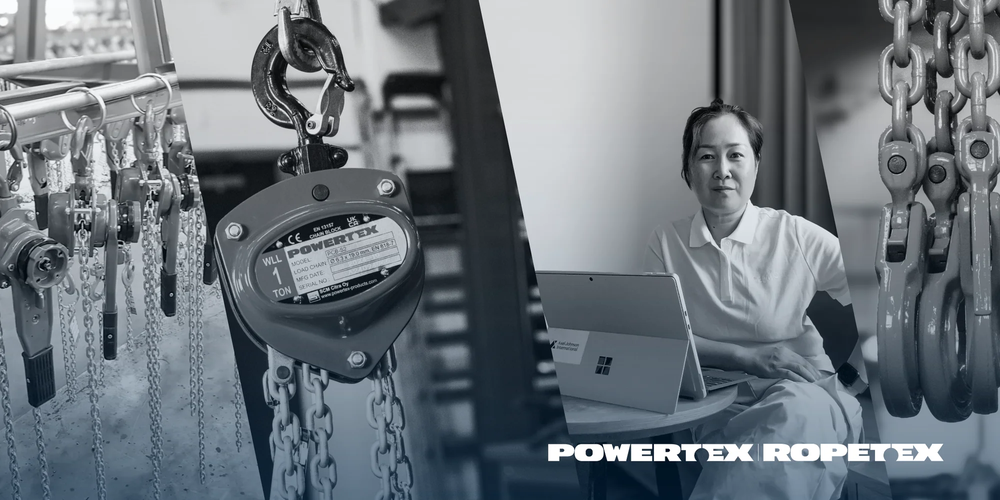

We spoke with Alice Yang, Regional Head of Sustainability Audit, to learn how our audit process supports fair working conditions, reduces environmental risks, and strengthens compliance with our standards.

A practical, partner-focused audit process

Before we start working with a new supplier, we will carry out a Code of Conduct compliance audit. This is repeated regularly once the collaboration begins. The audits focus on three areas:

- Business compliance, including business licenses and certifications

- Social responsibility, including fair pay and safe working conditions

- Environmental practices, such as handling of chemicals, waste, and pollution risks

“We prepare carefully before visiting a site,” says Alice. “We review online information, request a self-assessment from the supplier, and plan the audit based on the nature of the business. When we arrive, we make it clear that we are here as partners. Our goal is not just to check compliance, but to support them in making practical improvements”.

Supporting progress through practical change

Our audits often reveal opportunities for improvement, and we see our role as helping suppliers make those improvements in a practical way.

In one case, our audit team observed that while protective equipment was available, it was not being used consistently by workers on-site. Instead of simply reporting the issue, we worked with the management team to raise awareness, provide training, and improve routines for safer use of PPE. At the follow-up audit, the partner had introduced new measures and training sessions, and the correct use of protective equipment had significantly improved.

Another audit revealed an environmental risk: a waste tank that was not protected against rain, potentially allowing chemical run-off. We gave the manufacturer specific, cost-effective advice to fix the issue. They acted quickly, installing a cover and eliminating the risk.

These examples reflect a common theme: when our production partners understand the expectations and receive clear, hands-on support, they are willing and able to act. That is exactly the kind of progress we aim for.

Clear standards, strong partnerships

All production partners are evaluated using a performance scoring system. To move forward, they must meet minimum thresholds and show a clear willingness to improve. If a supplier does not meet the required standards after follow-up audits, the partnership does not continue. “This gives us confidence that we are working with partners who are committed to improvement,” says Alice.

Why this matters to our customers

For buyers and procurement teams, our compliance code of conduct audits are more than a behind-the-scenes process. They help improve supplier responsibility and reduce risks in the supply chain. You get:

- Reliable, compliant products

- Transparent sourcing practices

- Lower supply chain risk

- A partner that helps you meet your ESG goals

“Our audits are not about ticking boxes,” Alice concludes. “They are about building trust and improving together. When we raise standards across our supply chain, everyone benefits.”