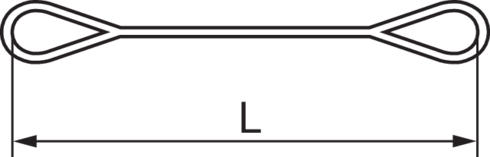

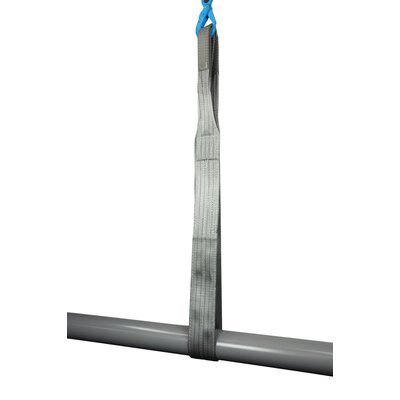

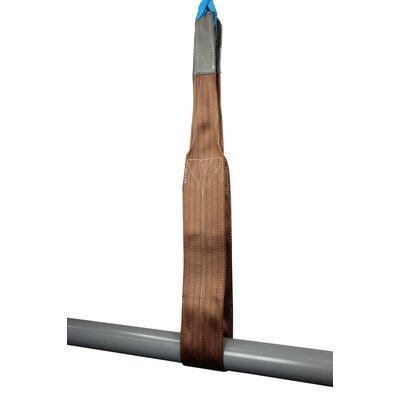

Powertex Webbing sling with eyes PWE are made from high strength polyester yarn having folded and reinforced eyes as standard.

The PWE slings are color coded for quick and easy identification of the Working Load Limit.

Only standard slings with full ton WLL are shown in the chart, but PWE slings can be delivered with any WLL and length on request.

- Safe – All Powertex PWE webbing slings are made from high strength industrial polyester and tested in accordance to EN 1492-1

- Flat woven, double lay webbing made in solid weaving

- Eyes are equipped with wear protection, from 2t and up, the eyes are also folded for improved handling.

- Each slings carry a blue label giving correct WLL for different load connection methods and angles

- Each sling is marked with a unique serial number for safe sling registration

- Year/Month calendar printed on the label where next inspection date can be marked or punched

- Printing on the blue label is protected by an additional transparent plastic layer for long life

- All slings carry a white label showing pictogram with important user warning instructions

- QR code for on-site access to Multilanguage user manuals

- Test certificate and Declaration of Conformity enclosed with each sling

Chemical resistance: Resistant to most acids, but not strong alkalizes

Stretch at working load: 2-3%

Length tolerance: Nominal length (EWL) ±3%.

- Material: Polyester

- Marking: According to standard, CE-marked, Powertex, WLL, EWL, manufacturing year, batch number, sling’s unique serial number, bar code, QR code, inspection calendar, user warning instructions

- Temperature range: -40°C up to +100°C.

- Standard: EN 1492-1

- Note: According to EN 1492-1:2000+A1:2008: D.3.7: Slings should be protected from edges, friction and abrasion, whether from the load or the lifting appliance. Where reinforcements and protection against damage from edges and/or abrasion is supplied as part of the sling, this should be correctly positioned. It may be necessary to supplement this with additional protection.

- Safety factor: 7:1